Infrastructure

Processing

Wrecking Yard

Scrap/Raw Material is often taken to a wrecking yard (also known as a scrapyard or breaker's yard), where it is processed for later melting into new products. In-house huge area allotted & common non-ferrous metals such as copper, brass, aluminum, zinc, magnesium, tin, nickel, and lead are sorted from mix scrap & moved to each defined area.

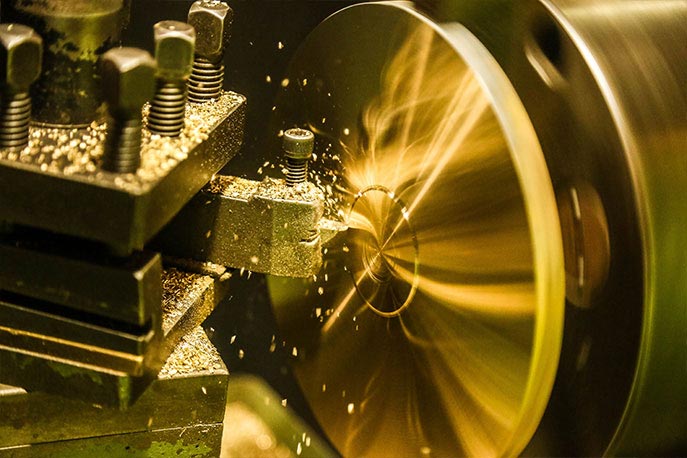

Melting and Casting

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. We have Horizontal continuous casters running 24x7 throughout a year is the biggest asset of the company.

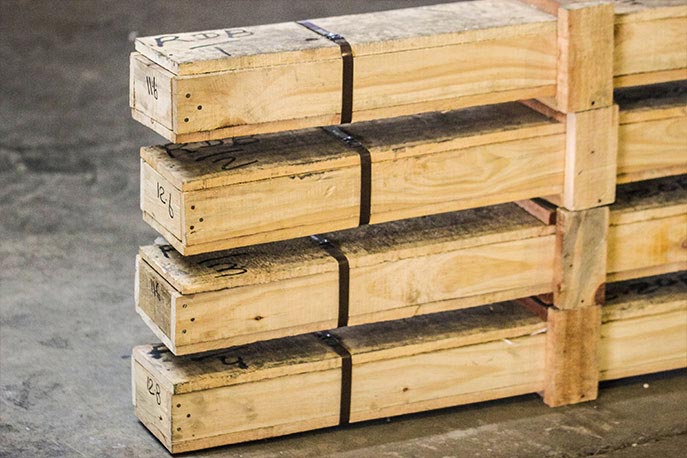

Depot

We define material storage locations made up of storage areas and storage levels. A material storage location is a division of our business unit used to store material and to track inventory transactions. This include the storage of semi-finish material that is stored for further processing & order execution. Each material storage location is identified by area and level.

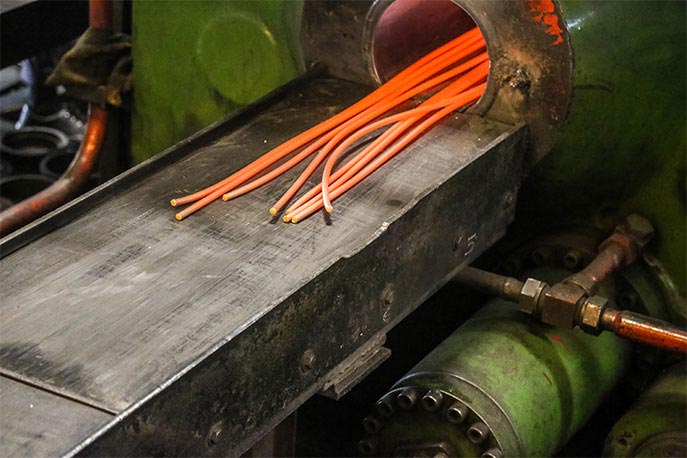

Extrusion

In our present set up we have three extrusion press of different tonnage helps us make different shapes of different alloys for achieving a perfect mix. Two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections, and to work materials that are brittle.

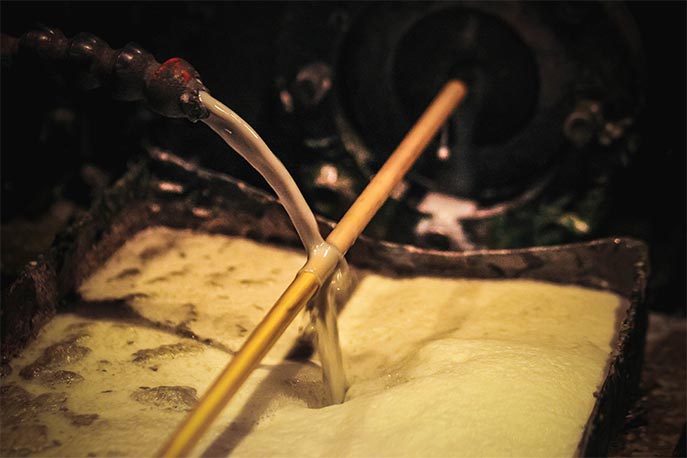

Pickling

Pickling is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, rust or scale from nonferrous metals. Pickling bath for copper or its alloys which not only removes oxide scales satisfactorily, but avoids the formation of red colorations and produces bright and smooth surfaces having an appearance which is more natural to the copper or alloy.

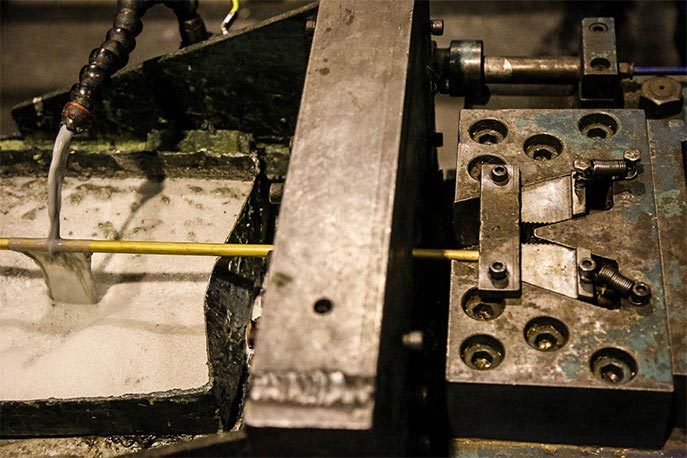

Rod Processing

Our Combined Drawing Machine is a complex combination of Drawing Machines, with high production efficiency, guaranteed to achieve the best quality finish. The wire straightener ensure the alignment of the wire material with in the drawing system in horizontal and vertical plane & the multi roll straightener ensure precise straightness and high surface quality. The entire system is controlled and operated using a moderate PLC control system.

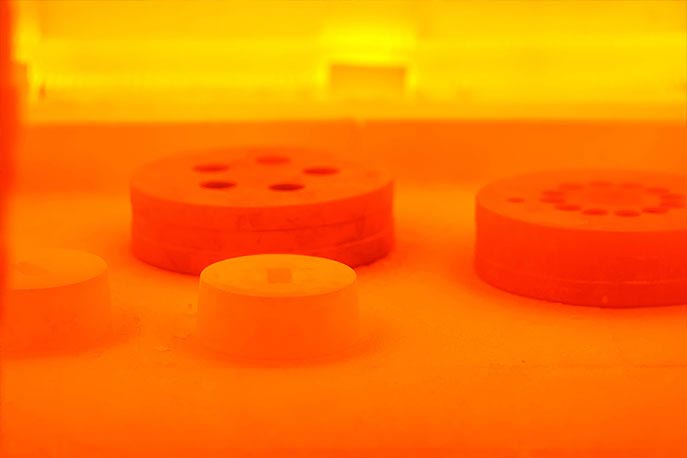

Heat Treatment

In-house heat treatment facilities involve three basic steps: heating, soaking, and cooling. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering. The three stages of the heat treatment process that proceed as the temperature of the material is increased are: recovery, re-crystallization, and grain growth.

Final Inspection

It is an inspection in the manufacturing process, and refers to the inspection performed in the final stage of manufacturing process. On top of that, the manufacturing process includes Acceptance Inspection and Inspection between Processes, both of which are performed by our highly skilled engineers for such constituent items as purchased raw materials and processed material.

Packaging

Packing associate are responsible for cleaning packaging materials, loading items into containers, and weighing and labeling the items appropriately. They also perform final checks for defective items, ensure all working items make it to the loading area or inventory, and keep detailed records of materials and shipments.

Supporting Facility

Radiation Testing

This includes: electromagnetic radiation such as radio waves, visible light, and x-rays. Particle radiation such as a, β, and neutron radiation. Mainly used to check radioactive substance in material. In-house facility & our system ensures that we deliver the material free from radioactive substance.

Weighbridge

Weighbridges are mainly used for weighing large vehicles like trucks or heavy vehicles where movement of goods is done through vehicles. In-house, reliable and accurate weighing helps the industry by giving them the exact figures to maintain their goods inward and goods outward. We have our in house weigh bridge scale.

Chemical Testing Lab

Our accredited material testing lab is fully equipped with highly technical staff & machines to test Metals and Alloys. The data and test results can determine for their intended applications and meet the requirements of regulatory agencies, design engineers or a business quality programs. Test specimens and samples are prepared right in our lab for efficient turnaround.

Tool Room

Any goods manufacturer seeking to introduce a new product likely requires customized required tools, dies and molds to make metal. In-house structure & equipment for making jigs, fixtures, dies, molds, machine tools, cutting tools, gauges, and other tools used in manufacturing processes is one of the core infrastructure that we have.

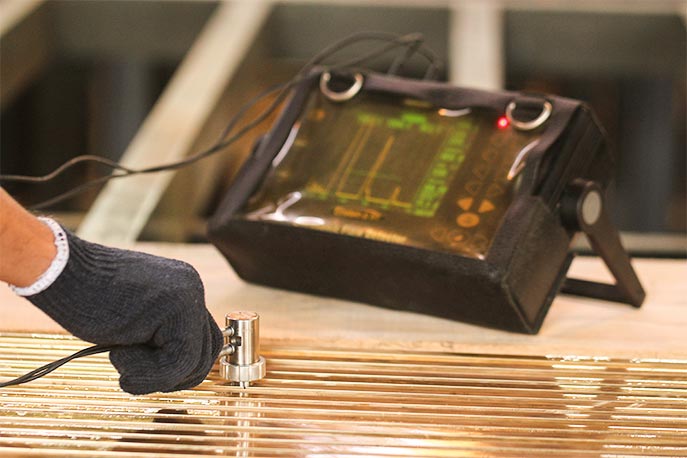

Ultrasonic Testing

Ultrasonic testing (UT) is a non-destructive test method that utilizes sound waves to detect cracks and defects in parts and materials. Also known as ultrasonic NDT or simply UT. Using in-house testing equipment & highly experienced & certified engineers, we provide a one-stop solution for such testing of materials.

Micro Structure Testing

The structure of a material can be described through its micro structure and crystal structure. Micro structures of metals and alloys have an immense impact on materials properties.Therefore, understanding grain micro structures and their changes due to re crystallization and grain growth is of great importance since a change in micro structure leads to a change of the materials properties.Our metallurgical microscopes and software are capable enough for capturing images and making measurements.

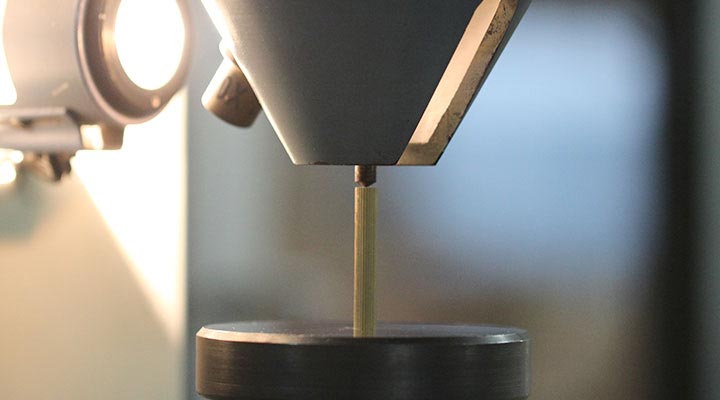

Mechanical Testing Lab

Laboratory testing plays an essential role throughout the entire product life cycle in research and development, qualification, manufacturing and operations. Our testing solutions include: Definition of test specifications, Execution of tests, Expert support such as results interpretation, failure analysis and recommendation of material and design and production of ad-hoc testing means to meet specific needs.

Water Treatment Plant

Wastewater treatment is fundamental to protect the health of many different ecosystems. In- house waste water treatment equipment used to convert waste water into an effluent that can be returned to the water cycle with minimum impact on the environment, or directly reused. The latter is called water reclamation because treated wastewater can then be used for other purposes.

Fume Exhauster

A fume exhaust system is used to capture these gases, dusts, mists and metal fumes in a work process. It consists collection hood, ducting, air cleaning device and blower and an effective fume extraction system can carry away airborne contaminants before they can be breathed in. Fume exhaust system are used widely in our foundries and are designed to capture and remove air-borne hazardous substances generated during melting and casting (e.g. gases, vapors, aerosols and particulates/dust).

Processing

Wrecking Yard

Scrap/Raw Material is often taken to a wrecking yard (also known as a scrapyard or breaker's yard), where it is processed for later melting into new products. In-house huge area allotted & common non-ferrous metals such as copper, brass, aluminum, zinc, magnesium, tin, nickel, and lead are sorted from mix scrap & moved to each defined area.

Melting and Casting

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. We have Horizontal continuous casters running 24x7 throughout a year is the biggest asset of the company.

Depot

We define material storage locations made up of storage areas and storage levels. A material storage location is a division of our business unit used to store material and to track inventory transactions. This include the storage of semi-finish material that is stored for further processing & order execution. Each material storage location is identified by area and level.

Extrusion

In our present set up we have three extrusion press of different tonnage helps us make different shapes of different alloys for achieving a perfect mix. Two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections, and to work materials that are brittle.

Pickling

Pickling is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, rust or scale from nonferrous metals. Pickling bath for copper or its alloys which not only removes oxide scales satisfactorily, but avoids the formation of red colorations and produces bright and smooth surfaces having an appearance which is more natural to the copper or alloy.

Rod Processing

Our Combined Drawing Machine is a complex combination of Drawing Machines, with high production efficiency, guaranteed to achieve the best quality finish. The wire straightener ensure the alignment of the wire material with in the drawing system in horizontal and vertical plane & the multi roll straightener ensure precise straightness and high surface quality. The entire system is controlled and operated using a moderate PLC control system.

Heat Treatment

In-house heat treatment facilities involve three basic steps: heating, soaking, and cooling. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering. The three stages of the heat treatment process that proceed as the temperature of the material is increased are: recovery, re-crystallization, and grain growth.

Final Inspection

It is an inspection in the manufacturing process, and refers to the inspection performed in the final stage of manufacturing process. On top of that, the manufacturing process includes Acceptance Inspection and Inspection between Processes, both of which are performed by our highly skilled engineers for such constituent items as purchased raw materials and processed material.

Packaging

Packing associate are responsible for cleaning packaging materials, loading items into containers, and weighing and labeling the items appropriately. They also perform final checks for defective items, ensure all working items make it to the loading area or inventory, and keep detailed records of materials and shipments.

Supporting Facility

Radiation Testing

This includes: electromagnetic radiation such as radio waves, visible light, and x-rays. Particle radiation such as a, β, and neutron radiation. Mainly used to check radioactive substance in material. In-house facility & our system ensures that we deliver the material free from radioactive substance.

Weighbridge

Weighbridges are mainly used for weighing large vehicles like trucks or heavy vehicles where movement of goods is done through vehicles. In-house, reliable and accurate weighing helps the industry by giving them the exact figures to maintain their goods inward and goods outward. We have our in house weigh bridge scale.

Chemical Testing Lab

Our accredited material testing lab is fully equipped with highly technical staff & machines to test Metals and Alloys. The data and test results can determine for their intended applications and meet the requirements of regulatory agencies, design engineers or a business quality programs. Test specimens and samples are prepared right in our lab for efficient turnaround.

Tool Room

Any goods manufacturer seeking to introduce a new product likely requires customized required tools, dies and molds to make metal. In-house structure & equipment for making jigs, fixtures, dies, molds, machine tools, cutting tools, gauges, and other tools used in manufacturing processes is one of the core infrastructure that we have.

Ultrasonic Testing

Ultrasonic testing (UT) is a non-destructive test method that utilizes sound waves to detect cracks and defects in parts and materials. Also known as ultrasonic NDT or simply UT. Using in-house testing equipment & highly experienced & certified engineers, we provide a one-stop solution for such testing of materials.

Micro Structure Testing

The structure of a material can be described through its micro structure and crystal structure. Micro structures of metals and alloys have an immense impact on materials properties.Therefore, understanding grain micro structures and their changes due to re crystallization and grain growth is of great importance since a change in micro structure leads to a change of the materials properties.Our metallurgical microscopes and software are capable enough for capturing images and making measurements.

Mechanical Testing Lab

Laboratory testing plays an essential role throughout the entire product life cycle in research and development, qualification, manufacturing and operations. Our testing solutions include: Definition of test specifications, Execution of tests, Expert support such as results interpretation, failure analysis and recommendation of material and design and production of ad-hoc testing means to meet specific needs.

Water Treatment Plant

Wastewater treatment is fundamental to protect the health of many different ecosystems. In- house waste water treatment equipment used to convert waste water into an effluent that can be returned to the water cycle with minimum impact on the environment, or directly reused. The latter is called water reclamation because treated wastewater can then be used for other purposes.

Fume Exhauster

A fume exhaust system is used to capture these gases, dusts, mists and metal fumes in a work process. It consists collection hood, ducting, air cleaning device and blower and an effective fume extraction system can carry away airborne contaminants before they can be breathed in. Fume exhaust system are used widely in our foundries and are designed to capture and remove air-borne hazardous substances generated during melting and casting (e.g. gases, vapors, aerosols and particulates/dust).